Post Harvest loss and its Management

Introduction

According to The FAO The world population will reach 9 billion by 2050and to feed this population the food production should be increased by 70%. Hence there is need for an innovative approach to the global effort of ensuring sustainable food production and consumption. Meanwhile, vast amounts of food are lost each year due to spoilage and infestations on the way to consumers, despite the fact that the number of people in the globe who are food insecure remains unacceptably high. Reducing these losses is, without a doubt, one of the most important methods to improve food security.

What is Postharvest loss ?

The term “postharvest loss” – PHL refers to measurable quantitative and qualitative food loss in the postharvest system (de Lucia and Assennato, 1994).From the moment of harvest, through agricultural processing, marketing, and meal preparation, to the consumer’s final decision to eat or discard the food, this system is made up of interlinked activities.

PHL is becoming more widely acknowledged as part of a comprehensive strategy for reaching agriculture’s full potential in meeting the world’s growing food and energy demands. As a result, lowering PHL, as well as making more effective use of today’s crops, increasing productivity on current farmland, and bringing additional area into production on a sustainable basis, is vital to meeting the issue of feeding and increasing population.

Factor promoting postharvest loss

- Spillage and grain loss in all postharvest processes such as Threshing, transport from field to storage house, winnowing, drying, storing, and milling, losses to animals and pests, and poor rice milling all contribute to the losses.

- In industrialized countries, one key cause is that a considerable portion of the food produced is rejected rather than being eaten, for reasons such as being left on the plate after a meal or having passed its expiration date.

- In contrast, in Less Developed Countries (LDCs), failure to consume accessible food is not a noted worry; rather, the low-quality food that remains in marketplaces at the end of the day is sustenance for the very poor. In LDCs, the problem is inefficient postharvest processing. Agricultural systems that result in the loss of food that would otherwise be consumed, are sold.

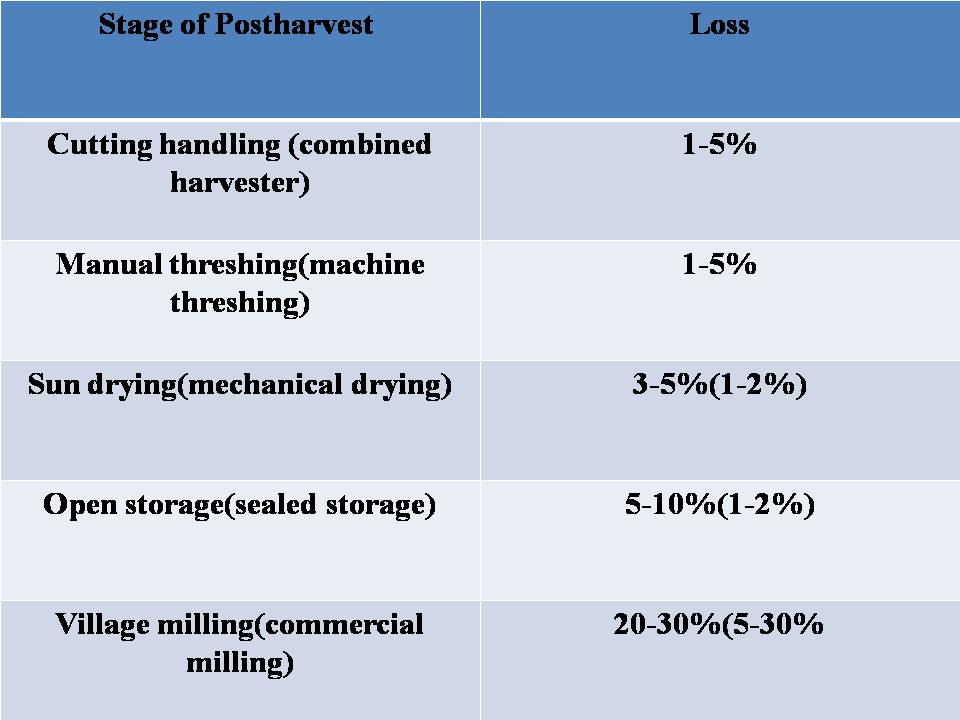

Estimated loss in various postharvest operations

Loss is the reduction in quantity and quality of food. Loss of quality and quantity occurs at various stages of postharvest is given in the table below:

Practices to reduce post-harvest losses

- Due to a lack of food or a severe need for income, poor farmers may harvest crops too early. The food loses nutritional and economic value as a result of this process. If it is unfit for ingestion, it may be thrown away. After harvest, quality can only be maintained, not increased. As a result, harvesting at the correct maturity stage and at the highest level of quality is critical.

- Most Farmers, both small and large, rely almost wholly on natural drying of crops, which involves combining sunlight with the circulation of atmospheric air through the product; as a result, wet weather during harvest can be a major source of postharvest losses. Grains should be dried in a way that minimizes grain degradation and maintains moisture levels below those needed to enable mold growth during storage (usually below 13-15 percent ). This is required to prevent growth of fungal species that may be present on fresh grains.

- Threshing may be delayed for several months after harvest for some grains, particularly millet and sorghum, with the unthreshed crop stored in open cribs.

- In the case of maize, the grain can be preserved on the cob for several months with or without sheathing leaves, or the cobs can be shelled and the grain stored separately. Maize shellers and rice mechanical threshers, both of which are actively supported by the International Rice Research Institute, are examples of machinery ideal for small-scale operations (IRRI).

- Both poor storage conditions and a lack of storage capacity are linked to post-harvest losses in storage. It is critical that stores be built in such a way that they provide dry, well-ventilated conditions that allow for additional drying in the event that complete drying prior to storage is not possible; protection from rain and ground water drainage; and protection from rat and bird intrusion.

एउटा यस्तो विषालु भ्यागुता, जसको मुल्य नै पर्छ ३ लाख, जान्नुहाेस्

एउटा यस्तो विषालु भ्यागुता, जसको मुल्य नै पर्छ ३ लाख, जान्नुहाेस्  भोलि र पर्सि बालबालिकालाई भिटामिन ए खुवाइदै

भोलि र पर्सि बालबालिकालाई भिटामिन ए खुवाइदै  खगराज अधिकारी गण्डकीको मुख्यमन्त्री नियुक्त

खगराज अधिकारी गण्डकीको मुख्यमन्त्री नियुक्त  सुनसरीमा दुवै पक्षबीच सहमति, कर्फ्यु खुकुलो हुदै

सुनसरीमा दुवै पक्षबीच सहमति, कर्फ्यु खुकुलो हुदै  स्टेफेनको शतकमा आयरल्याण्ड वोल्भ्सले नेपाल ए लाई दियो २८५ रनको लक्ष्य

स्टेफेनको शतकमा आयरल्याण्ड वोल्भ्सले नेपाल ए लाई दियो २८५ रनको लक्ष्य